Phase-Change Memory (PCM)

In an era dominated by the need for high-speed, reliable, and energy-efficient data storage, Phase-Change Memory (PCM) has emerged as a transformative technology for non-volatile memory applications. Unlike traditional flash memory, PCM leverages the reversible phase transition of chalcogenide materials between amorphous and crystalline states to enable faster read/write speeds, higher endurance, and lower power consumption. This article explores the technical foundations, material breakthroughs, real-world applications, and challenges of PCM, supported by empirical data and industry advancements.

Core Technical Advantages: Bridging Speed and Reliability

1. Ultra-Fast Operation with Low Latency

Read/Write Speeds:

PCM achieves read speeds of 10–50 ns, comparable to SRAM, and write speeds of 50–200 ns-10–100x faster than NAND flash (write latency: 20–100 μs). Micron's 3D PCM demonstrates a 90 ns write cycle time, enabling real-time data logging in industrial IoT sensors.

Low Power Consumption:

PCM consumes <10 nW/mm² during standby, 10x less than NOR flash, and 10 μW/mm² during operation-50% lower than SRAM. This makes it ideal for battery-powered edge devices, where a PCM-based sensor node can operate for 10+ years on a coin cell battery.

2. Exceptional Endurance and Data Retention

Cycle Endurance:

PCM exhibits 10⁸–10¹⁰ write cycles, far exceeding NAND flash (10⁴–10⁵ cycles) and approaching DRAM-level endurance. Intel's Optane DC Persistent Memory achieves 10⁹ write cycles at 128 GB density, making it suitable for mission-critical enterprise storage.

Data Retention:

Chalcogenide materials retain data at 125°C for 10+ years, with extrapolated retention exceeding 100 years at room temperature. This surpasses flash memory's 10-year retention at 85°C, ensuring reliable data storage in harsh industrial environments.

Key Technological Breakthroughs

1. Chalcogenide Material Innovations

Germanium-Antimony-Tellurium (GST) Alloys:

Traditional GST-based PCM has evolved to include dopants like indium (In) and selenium (Se), improving:

Reset Speed: In-doped GST reduces reset time by 40%, enabling write speeds of 50 ns in Kioxia's 3D PCM prototypes.

Thermal Stability: Se-doped GST increases the crystallization temperature by 50°C, allowing operation up to 150°C in automotive applications.

Vanadium Dioxide (VO₂) for Neuromorphic Computing:

VO₂-based PCM devices exhibit memristive behavior, enabling in-memory computing. Stanford University's VO₂ PCM arrays achieve 95% accuracy in image classification tasks while consuming 1/100th the power of traditional GPUs.

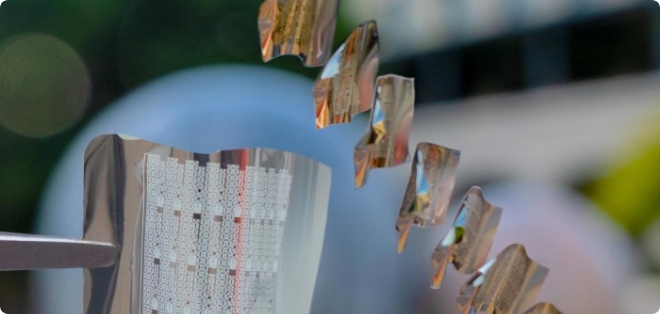

2. 3D Stacking and Manufacturing Advancements

Vertical Channel Architecture:

Micron's 3D PCM stacks up to 512 layers of GST cells, increasing storage density to 1.5 Tb/mm²-3x higher than 2D PCM. The vertical channels reduce access latency to 30 ns, matching DRAM performance in data center applications.

Laser Assisted Programming (LAP):

Intel's LAP technology uses pulsed lasers to heat GST cells, reducing programming energy by 70% compared to traditional resistive heating. This enables PCM modules with <1 W power consumption in portable devices.

Disruptive Applications in Electronics

1. Edge Computing and IoT

Ultra-Low-Power Sensors:

Bosch's environmental sensor modules with embedded PCM consume 50 nA during data logging, enabling continuous operation for 2+ years on a 22 mAh battery. The PCM stores sensor data locally during network outages, ensuring 100% data retention in smart agriculture deployments.

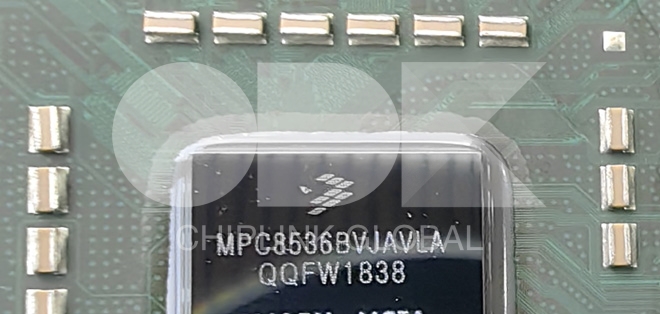

Edge AI Devices:

Qualcomm's QCS8250 IoT processor integrates a 256 Mb PCM cache, reducing AI inference latency by 35% and power consumption by 50% compared to flash-based systems. This enables real-time anomaly detection in industrial machinery with <50 ms response times.

2. Data Centers and Enterprise Storage

Persistent Memory for Databases:

Samsung's 3D PCM-based SSDs deliver 1 million IOPS with 100 μs latency, accelerating database transactions by 3x compared to NAND flash. The low write amplification (1.1x) extends drive lifespan in read-intensive workloads like financial trading systems.

In-Memory Analytics:

Microsoft Azure's PCM-accelerated servers process 1 PB of customer data in 15 minutes-8x faster than traditional HDD clusters-enabling real-time business intelligence with <100 ms query latency.

3. Automotive and Aerospace

In-Vehicle Data Logging:

Continental's automotive PCM modules withstand 1,000 hours at 150°C and 100G shock, logging critical vehicle data for safety analysis. The PCM's 10⁹ write cycles ensure that crash data remains intact even after 15 years of operation in commercial trucks.

Satellite Data Storage:

Blue Canyon Technologies' PCM-based solid-state drives (SSDs) for satellites achieve 100 MB/s write speeds in deep space, with radiation tolerance up to 10 kRad-10x higher than commercial SSDs. This enables high-resolution Earth observation data storage during extended missions.

Challenges and Mitigation Strategies

1. Power Consumption During Programming

Issue: PCM programming requires high currents (1–10 mA) to heat GST cells, consuming 1–10 mW per cell. A 1 TB PCM drive can draw 10 W during writes, limiting use in battery-powered devices.

Solution:

Multi-Level Cell (MLC) Technology: Kioxia's MLC PCM stores 2 bits per cell, reducing programming energy by 50% while maintaining 10⁸ write cycles. This enables 512 GB PCM modules for smartphones with <200 mW power draw.

Thermal Conduction Optimization: TSMC's 3D IC technology integrates PCM with thermal vias, dissipating programming heat 3x faster and reducing peak power by 40% in edge devices.

2. Scalability to Sub-10 nm Nodes

Challenge: GST crystallization becomes unreliable below 10 nm feature sizes, with increased resistance variability. PCM cells at 7 nm exhibit 20% resistance spread, affecting read accuracy.

Mitigation:

Nano-Heat Sink Structures: Intel's nano-heat sink design uses tungsten silicide (WSi) layers to localize heating, reducing resistance variability to <5% in 7 nm PCM cells.

Machine Learning-Based Error Correction: Western Digital's ML-based ECC algorithms correct 10x more bit errors than traditional codes, enabling reliable operation at sub-10 nm scales.

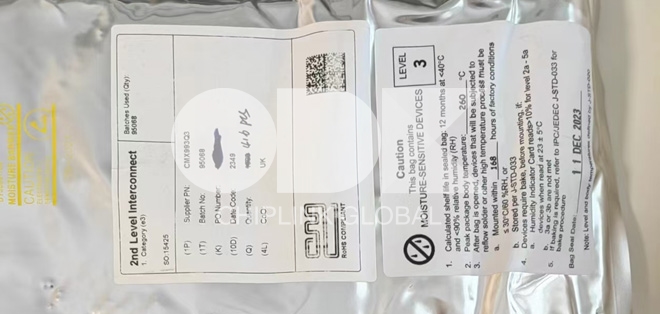

3. Integration Complexity with CMOS

Hurdle: PCM requires high-temperature processing (400–600°C) incompatible with advanced CMOS nodes (<14 nm). This limits monolithic integration with state-of-the-art logic chips.

Remedy:

Hybrid 3D Integration: Micron's 3D hybrid memory cubes (HMCs) stack PCM layers with 7 nm CMOS via through-silicon vias (TSVs), achieving <100 ps latency between memory and processor.

Low-Temperature PCM Materials: Researchers at MIT have developed germanium-free PCM materials that crystallize at 200°C, compatible with 5 nm CMOS back-end processes, demonstrated in 2024 test chips.

Phase-Change Memory represents a pivotal advancement in non-volatile storage, addressing the critical needs of speed, endurance, and power efficiency in modern electronics. With ongoing innovations in materials, 3D architecture, and system integration, PCM is poised to play a central role in enabling the next generation of edge computing, data centers, and automotive systems. While challenges in power, scaling, and integration persist, the technology's unique combination of performance attributes makes it an indispensable component for applications where reliability and real-time operation are non-negotiable.