Enabling High-Efficiency Energy Conversion in Electronics

In an era where energy efficiency and miniaturization drive advancements in electronic systems, gallium nitride (GaN) power devices have emerged as a transformative technology for power conversion applications. Unlike traditional silicon (Si) and silicon carbide (SiC) devices, GaN offers superior switching speeds, higher breakdown electric fields, and lower conduction losses, enabling power supplies and converters to operate at unprecedented efficiencies. This article explores the technical foundations, material breakthroughs, real-world applications, and challenges of GaN power devices, supported by empirical data and industry advancements.

Core Technical Advantages: Redefining Power Conversion Efficiency

1. Ultra-Fast Switching with Low Losses

Switching Speed:

GaN devices achieve switching frequencies of 100 kHz to 10 MHz-10–100x higher than silicon MOSFETs. EPC's GaN FETs switch in <10 ns, enabling power supplies to operate at 1 MHz with <1% switching losses. This allows for smaller inductors and capacitors, reducing power supply size by 50%.

Low Conduction Losses:

GaN has a specific on-resistance (RDS(on) × area) of 10 mΩ·mm²-3x lower than SiC and 10x lower than silicon. Navitas' GaN power ICs achieve 98% efficiency in 65W USB-C chargers, compared to 94% for silicon-based designs, reducing heat dissipation by 60%.

2. High Temperature and Voltage Capability

Temperature Resistance:

GaN devices operate reliably at junction temperatures up to 150°C-20°C higher than silicon. Texas Instruments' GaN power modules maintain 97% efficiency at 125°C, making them suitable for automotive under-the-hood applications.

Voltage Rating:

GaN transistors are available in voltage classes from 650V to 1200V, competing with SiC in medium-voltage applications. Infineon's 650V GaN HEMTs enable power factor correction (PFC) stages in 3kW solar inverters with 99% efficiency.

Key Technological Breakthroughs

1. Material and Device Architecture Innovations

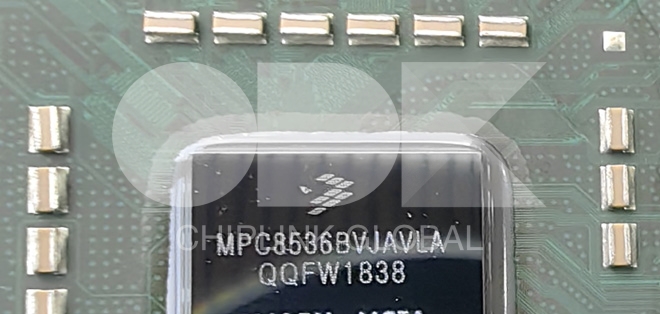

Monolithic Integration:

NXP's GaN-on-Si technology integrates gate drivers and protection circuitry with GaN FETs on a single die, reducing parasitic inductance by 70% and enabling switching speeds of 200 V/ns. The resulting modules have a power density of 100 W/mm³-4x higher than discrete solutions.

Enhancement-Mode (E-mode) Devices:

E-mode GaN devices, such as those from Qorvo, eliminate the need for negative gate voltages, simplifying drive circuitry. This reduces system complexity and cost by 30% in consumer electronics applications.

2. Manufacturing Process Advancements

Thin-Film GaN on Silicon:

AIXTRON's metal-organic chemical vapor deposition (MOCVD) systems produce GaN layers with <10^9 cm⁻³ defect density on 200 mm silicon wafers, reducing material costs by 40% compared to GaN-on-SiC.

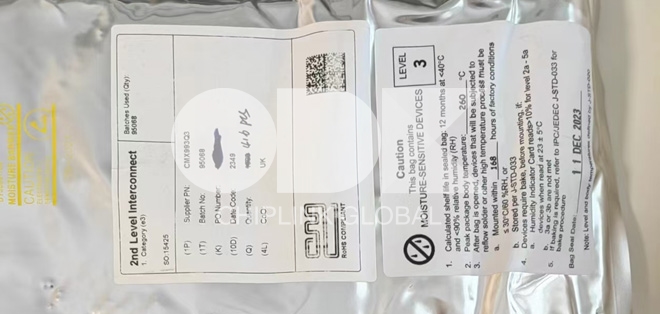

3D Packaging Technologies:

STMicroelectronics' 3D GaN packaging uses through-silicon vias (TSVs) to connect multiple GaN dies, achieving 500 A/mm² current density-2x higher than traditional wire-bonded packages. This enables 10kW EV charging modules in a 100 cm³ form factor.

Disruptive Applications in Electronics

1. Consumer Electronics

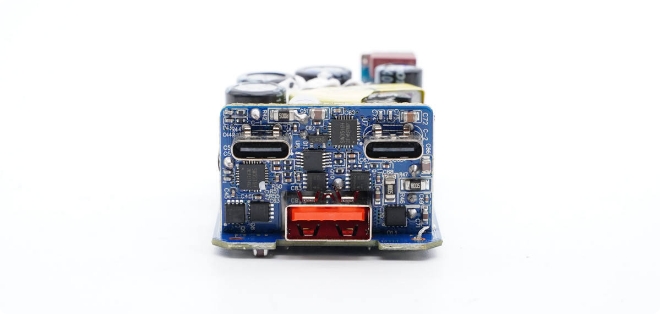

Ultra-Compact Power Supplies:

GaN-based chargers like the Xiaomi 120W GaN charger are 60% smaller than silicon counterparts while maintaining full power output. The charger delivers 120W at 96% efficiency, charging a 4000 mAh battery from 0–100% in 18 minutes.

Audio Amplifiers:

Class-D audio amplifiers using GaN FETs from Efficient Power Conversion (EPC) achieve 95% power efficiency with <0.1% total harmonic distortion (THD). This enables portable speakers to produce 100W of audio power while running for 20 hours on a 5000 mAh battery.

2. Electric Vehicles (EVs) and Charging

On-Board Chargers (OBCs):

Wolfspeed's GaN OBCs for EVs achieve 97.5% efficiency in 3.3kW systems, reducing charging time by 25% compared to silicon. The compact design (1.5L volume) fits easily into vehicle chassis, supporting bi-directional charging for vehicle-to-grid (V2G) applications.

DC-DC Converters:

GaN-based DC-DC converters in EVs step down 400V battery power to 12V for auxiliary systems with 98% efficiency, saving 500W of power-equivalent to extending EV range by 5 km per charge.

3. Renewable Energy and Grid Infrastructure

Solar Inverters:

SolarEdge's 10kW GaN inverter achieves 99.5% peak efficiency, increasing energy harvest by 1.2% compared to SiC designs. Over a 20-year lifespan, this translates to 24,000 kWh of additional energy production for a typical residential solar system.

Grid-Tied Energy Storage:

GaN converters in battery energy storage systems (BESS) enable round-trip efficiencies of 96%, reducing energy losses by 40% compared to silicon. Tesla's Megapack uses GaN devices to support 1.5 MWh systems with sub-100 ms response times for grid stabilization.

Challenges and Mitigation Strategies

1. Cost and Scalability

Issue: GaN wafers cost 3–5x more than silicon, with a 200 mm GaN-on-Si wafer priced at

500 for silicon. This makes GaN devices 2–3x more expensive than silicon in low-power applications.

Solution:

Economies of Scale: GaN-on-Si production is scaling to 300 mm wafers, with Taiwan Semiconductor Manufacturing Company (TSMC) planning 100,000 wafers/year by 2026, aiming to reduce costs by 50%.

Material Substitution: Aluminum gallium nitride (AlGaN) alloys reduce GaN layer thickness by 30%, lowering material usage and costs for high-voltage devices.

2. Reliability and Thermal Management

Challenge: GaN devices have a higher thermal resistance (5–10°C/W) than silicon, requiring advanced cooling solutions. In high-power applications, inadequate thermal management can lead to 10% reduction in device lifespan for every 10°C increase in junction temperature.

Mitigation:

Diamond Heat Sinks: II-VI's diamond heat spreaders have a thermal conductivity of 2,000 W/m·K-5x higher than copper-reducing thermal resistance by 60% in GaN power modules.

Active Thermal Control: Analog Devices' GaN drivers include integrated temperature sensors that adjust switching frequency in real-time, maintaining junction temperatures below 125°C under varying loads.

3. Device Protection and Circuit Design

Hurdle: GaN's fast switching speeds (>100 V/ns) can generate voltage overshoots of 200V in unprotected circuits, risking device failure. Traditional silicon-based protection circuits are too slow to respond.

Remedy:

Integrated Protection Features: onsemi's NXH series GaN FETs include integrated gate-source clamping diodes that limit voltage overshoot to <50V, eliminating the need for external snubber circuits and reducing component count by 20%.

AI-Based Drive Optimization: ON Semiconductor's GaN drive ICs use machine learning to optimize gate drive waveforms, reducing voltage overshoot by 30% and improving system reliability.

Gallium nitride power devices represent a paradigm shift in energy conversion, enabling smaller, more efficient electronic systems across consumer, automotive, and energy sectors. With ongoing advancements in materials, manufacturing, and circuit design, GaN is set to displace silicon in high-performance power applications, driving innovation in renewable energy, electric mobility, and next-generation electronics. While challenges in cost and thermal management persist, the technology's unique combination of efficiency and power density makes it an indispensable component for the green energy transition and global decarbonization efforts.