High frequency thyristor and bidirectional thyristor capsule series

ODK (HK) Electronics Technology CO., LIMITED, as a professional power semiconductor device supplier, is committed to providing high-performance and high reliability solutions. Its high-frequency thyristor (capsule version) and bidirectional thyristor/welding machine grade diode and thyristor (capsule version) series products are designed to meet the demanding needs of the industrial power electronics field.

Core products and application areas

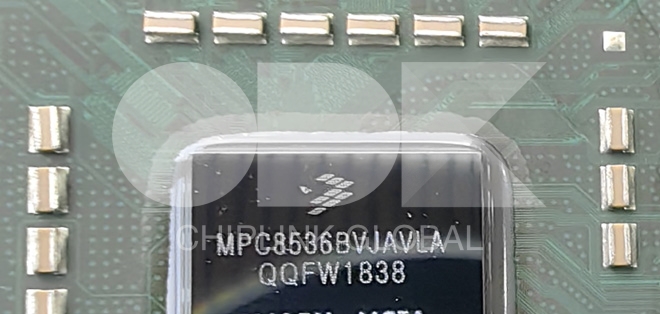

1. High frequency thyristor (capsule version):

• Core advantages: low switching losses, high dynamic characteristics, short recovery time, high operating frequency.

Specially optimized design, perfectly adapted to high-frequency switch applications.

• Key applications:

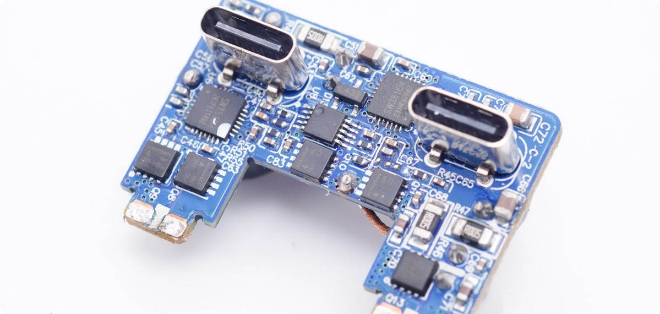

Inverter Welders: The core power switching device of modern high-efficiency welding machines, achieving precise energy control and improving welding quality.

Industrial inverters: widely used in variable frequency drives

UPS\

New energy conversion systems such as solar/wind power generation.

Choppers: fields such as DC motor speed regulation and power quality control.

Current converters: applications such as high-power DC power supplies, electroplating, and electrolysis.

Market demand driven:

Industrial automation upgrade: The demand for high-efficiency, energy-saving, and precisely controlled variable frequency drives and welding equipment has surged.

New energy development: The market for photovoltaic inverters, energy storage converters, and other products continues to expand, requiring high-performance power switches.

Technological innovation in welding equipment: Digitized, high-frequency, and miniaturized welding machines are the mainstream trend in the market, with extremely high requirements for core power components.

2. Bidirectional thyristor/welding machine level diode and thyristor (Capsule Version):

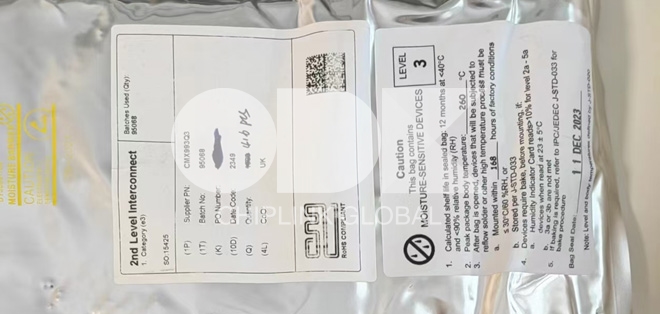

Core advantage: The "Ceramic disc type bipolar eutectic" process ensures high sealing, electrical isolation, and heat dissipation performance.

Strong surge tolerance.

• Key applications:

Welders: As a key component for rectifying and controlling the main power supply of the welding machine.

Market demand driven: The welding machine manufacturing industry has continuously increased its requirements for the durability, reliability, and power density of core power devices, especially in the heavy industry and automated welding fields.