Micro-Electro-Mechanical Systems (MEMS) Actuators

In an age where miniaturization and precision control are paramount, Micro-Electro-Mechanical Systems (MEMS) actuators have emerged as critical components for enabling precise motion in devices ranging from smartphones to medical implants. Unlike traditional electromagnetic or hydraulic actuators, MEMS actuators leverage microfabrication techniques to create miniature mechanical systems driven by electrostatic, piezoelectric, or thermal forces. This article delves into the technical foundations, material breakthroughs, real-world applications, and challenges of MEMS actuators, supported by empirical data and industry advancements.

Core Technical Advantages: Miniaturization Meets Precision

1. Ultra-Small Form Factor with High Performance

Size Reduction:

MEMS actuators typically measure 10–1000 μm in size, enabling integration into compact devices. For example, the MEMS mirror in the Apple iPhone LiDAR scanner measures just 500 μm x 500 μm, yet achieves ±15° angular deflection for 3D environment mapping.

Massive Parallelism:

Arrays of MEMS actuators can be batch-fabricated on silicon wafers, with a single 12-inch wafer producing 10,000+ actuators. This parallelism reduces costs to $0.10 per actuator for high-volume applications like autofocus mechanisms in camera modules.

2. Precision Motion Control

Positioning Accuracy:

Piezoelectric MEMS actuators achieve <1 nm positional resolution, critical for semiconductor manufacturing. Applied Materials' MEMS stage actuators enable 0.5 nm precision in extreme ultraviolet (EUV) lithography systems, essential for 3 nm chip fabrication.

Fast Response Times:

Electrostatic MEMS actuators exhibit response times of 1–100 μs, outperforming traditional solenoids (1–10 ms). This speed enables high-frequency operations, such as the 10,000 Hz resonance frequency of Knowles' MEMS speakers, delivering crisp audio in true wireless earbuds.

Key Technological Breakthroughs

1. Material Innovations for Actuation

Piezoelectric Materials:

Lead zirconate titanate (PZT) thin films sputtered onto silicon substrates offer high actuation efficiency, with a voltage coefficient of 200 pm/V. TDK's piezoelectric MEMS actuators using PZT films achieve 500 nm displacement at 10 V, ideal for autofocus in smartphone cameras.

Shape Memory Alloys (SMAs):

Nickel-titanium (NiTi) SMAs enable thermal actuation with large displacements. Nissha's SMA-based MEMS grippers produce 100 μm displacement at 80°C, used in minimally invasive surgical tools to grasp tissues with 10 mN precision.

2. Manufacturing Process Advancements

3D Microfabrication:

Bosch's deep reactive ion etching (DRIE) process creates high-aspect-ratio structures, with feature depths reaching 500 μm while maintaining 1 μm lateral precision. This enables MEMS actuators with complex 3D geometries, such as the 5-layer stacked actuators in Bosch's automotive airbag accelerometers.

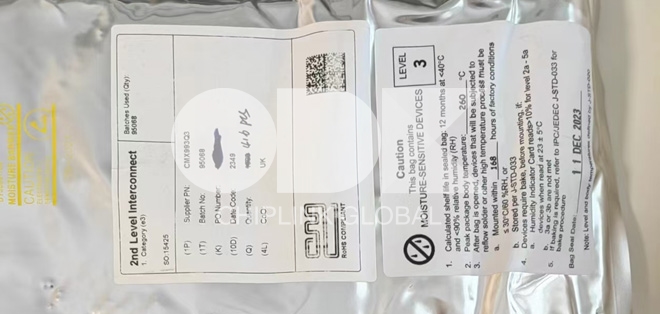

Wafer-Level Packaging (WLP):

TSMC's WLP for MEMS actuators reduces package size by 70% compared to traditional ceramic packages. The hermetic seal achieved via silicon fusion bonding maintains actuator performance in harsh environments, with leak rates < 10⁻⁹ mbar·L/s.

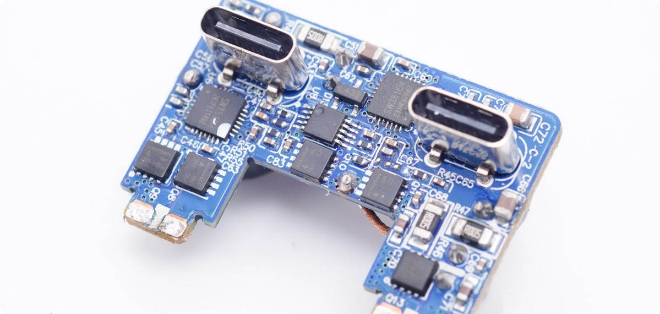

Disruptive Applications in Electronics

1. Consumer Electronics

Haptic Feedback in Wearables:

STMicroelectronics' MEMS linear resonant actuators (LRAs) produce 100 mN force with 5 ms rise time, enabling precise tactile feedback in smartwatches. The Apple Watch Series 8 uses MEMS LRAs to deliver 20+ distinct haptic patterns for user interactions.

Adaptive Lenses in Cameras:

Oppo's MEMS-based liquid lens actuators adjust focal length in 2 ms, enabling 5x optical zoom in smartphones. The actuators achieve 0.1 diopter precision, outperforming traditional voice coil motors (VCMs) which take 20 ms for similar adjustments.

2. Medical Devices

Drug Delivery Systems:

Medtronic's MEMS micropumps use piezoelectric actuators to deliver insulin with 1 nL precision at 100 μL/hour. The actuators operate for 3+ years on a coin cell battery, reducing replacement surgeries for diabetes patients.

Endoscopic Manipulators:

Intuitive Surgical's da Vinci SP system employs MEMS actuators in its robotic endoscope, achieving 0.1 mm tip precision for minimally invasive surgeries. The actuators' 100 Hz update rate matches human hand movements, enabling surgeons to perform delicate procedures with confidence.

3. Automotive and Aerospace

Adaptive Suspension Systems:

Continental's MEMS hydraulic actuators adjust shock absorbers in 5 ms, improving vehicle stability on rough terrain. The actuators, measuring 10 mm³, produce 50 N force while consuming <1 W-10x more efficient than traditional solenoid valves.

Satellite Attitude Control:

Blue Canyon Technologies' MEMS reaction wheels use electrostatic actuators to generate 100 μN·m torque for satellite orientation. The actuators, weighing 100 g, enable precise pointing with 0.01° accuracy, critical for Earth observation satellites.

Challenges and Mitigation Strategies

1. Power Consumption in Continuous Operation

Issue: Piezoelectric MEMS actuators consume 1–10 mW during operation, limiting battery life in portable devices. For example, a MEMS mirror in a head-mounted display (HMD) running continuously at 10 mW reduces battery life by 20%.

Solution:

Energy Harvesting Integration: Texas Instruments' MEMS actuators with integrated piezoelectric energy harvesters generate 10 μW from ambient vibrations, offsetting 50% of operational power in industrial sensors.

Pulse Width Modulation (PWM): STMicroelectronics' actuators use PWM to operate in burst modes, reducing average power to 1 μW while maintaining performance, as seen in their MEMS microphones for always-on voice assistants.

2. Reliability in Harsh Environments

Challenge: High-temperature operation ( >125°C) degrades piezoelectric materials, with PZT losing 15% actuation efficiency after 1,000 hours at 150°C. This limits use in automotive under-the-hood applications.

Mitigation:

High-Temperature Materials: Kyocera's lanthanum-doped lead zirconate titanate (PLZT) actuators maintain 95% performance at 200°C, used in engine control units (ECUs) for commercial vehicles.

Hermetic Encapsulation: TE Connectivity's hermetically sealed MEMS actuators use glass-to-silicon anodic bonding, preventing moisture ingress and maintaining reliability in marine environments with <0.1% performance degradation over 5 years.

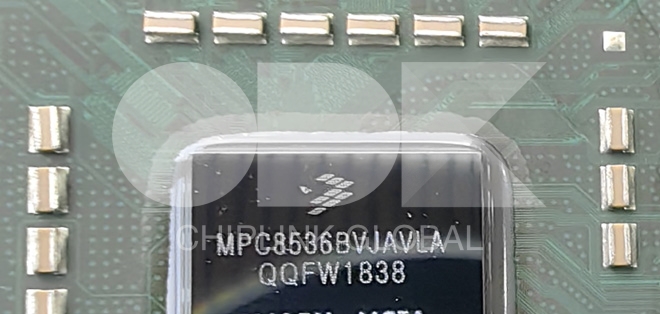

3. Integration Complexity with Electronics

Hurdle: MEMS actuators require precise drive circuitry, adding 30% to system cost when integrated with microcontrollers. For example, a MEMS stage actuator for microscopy costs

50∗∗withdrivers,versus∗∗

30 for the actuator alone.

Remedy:

System-in-Package (SiP) Integration: Analog Devices' iMEMS® platform integrates actuators with CMOS drivers in a single package, reducing cost by 25% and simplifying design for customers.

Open-Source Drivers: The MEMS Industry Group (MIG) promotes open-source driver libraries, such as the MIG Actuator API, reducing development time from 6 months to 2 months for new applications.

MEMS actuators represent a critical enabler for precision motion control in miniaturized systems, bridging the gap between microscale fabrication and macroscale functionality. As materials science and manufacturing techniques advance, MEMS actuators will continue to drive innovation in consumer electronics, healthcare, and aerospace-enabling technologies that were once the realm of science fiction. While challenges in power, reliability, and integration persist, the ongoing evolution of MEMS actuator technology promises to unlock new frontiers in miniaturized precision control.